PR-3000-FS-N01 Wind speed transmitter

Posted on: November 8, 2021, in All, Python, Raspberry Pi

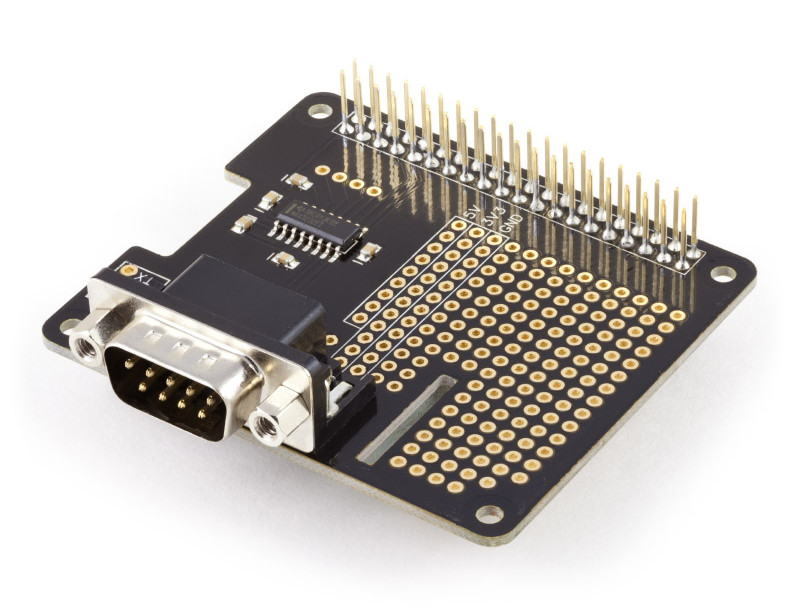

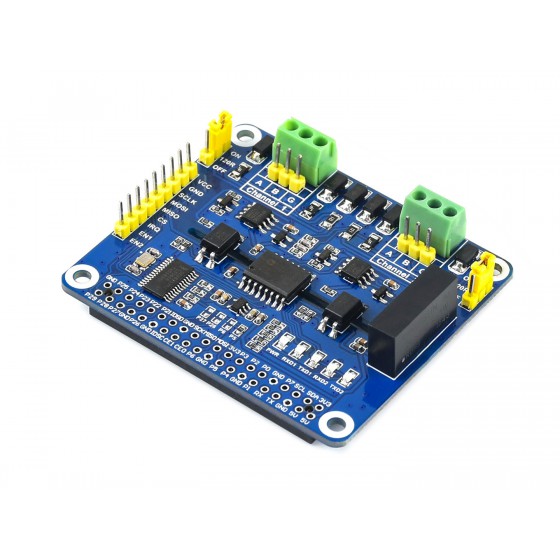

This describes getting a FS-N01 anemometer working with some python 3 code on a Raspberry PI with a Waveshare 2 channel RS485 hat.

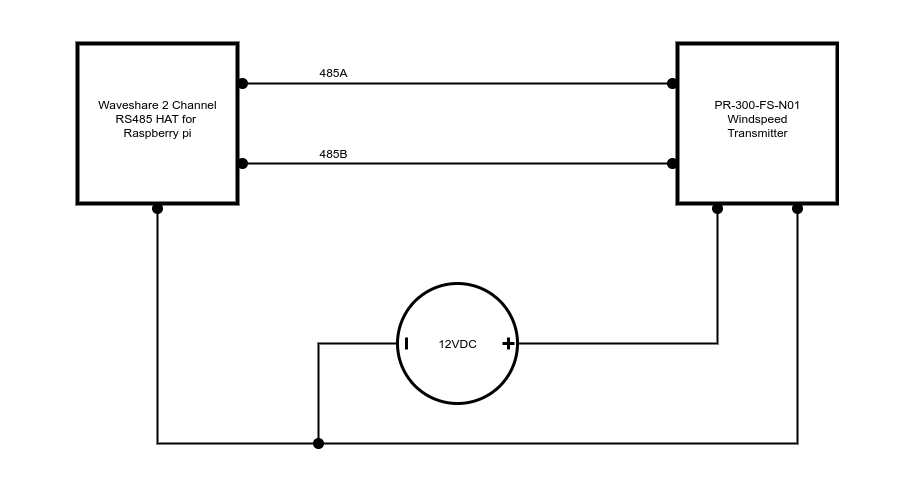

The anemometer has Chinese markings on it for V+, V-, 485A and 485B. Obviously the V+ and V- are for power supply and I used 12VDC. The manual I found online states 10-30VDC.

The RS485 lines are marked with a Chinese symbol for their colour. My manual stated Yellow and blue and yet the device I have was Green and Blue. Just lookup the corresponding Chinese character and get the translation for the colour if you don’t speak the language. Mine was:

The Waveshare 2 channel RS485 hat required an edit to the /boot/config.txt file of the raspberry pi. Add the following line and then reboot.

dtoverlay=sc16is752-spi1,int_pin=24

You should now see 2 devices in /dev:

/dev/ttySC0 and /dev/ttySC1, these of course are your serial ports.

Copy the python3 code below and your wind speed should be displayed in Kilometers per hour when you run it.

#!/usr/bin/python3

# -*- coding:utf-8 -*-

# Copyright (C) 2021 George Farris <farrisg@gmsys.com>

#

# This program is free software: you can redistribute it and/or modify

# it under the terms of the GNU General Public License as published by

# the Free Software Foundation, either version 3 of the License, or

# (at your option) any later version.

# This program is distributed in the hope that it will be useful,

# but WITHOUT ANY WARRANTY; without even the implied warranty of

# MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

# GNU General Public License for more details.

# You should have received a copy of the GNU General Public License

# along with this program. If not, see <http://www.gnu.org/licenses/>.

# Anemometer.py is reference code to read a PR-3000-FS-N01, RS465 Anemometer

# on a raspberry pi 4 using a Waveshare 2 channel RS485 HAT.

# https://www.waveshare.com/2-ch-rs485-hat.htm

import serial

import os

import sys

import time

import RPi.GPIO as GPIO

SERIAL_PORT = "/dev/ttySC0"

TXDEN_1 = 27

TXDEN_2 = 22

# Calculate CRC16 Checksum

def _crc16(data, no):

crc = 0xffff

poly = 0xa001 # Polynomial used for Modbus RS485 applications

temp = no

while True:

crc ^= data[temp - no]

for i in range(0, 8):

if crc & 0x0001:

crc = (crc>>1) ^ poly

else:

crc >>= 1

no -= 1;

if no == 0:

break

return crc & 0xffff

# Open the serial port at 4800 buad

ser = serial.Serial(port=SERIAL_PORT, baudrate=4800)

# Set the mode on the Raspberry Pi GPIO

GPIO.setmode(GPIO.BCM)

# Set this to avoid warning of channel in use

GPIO.setwarnings(False)

# Set the GPIO pin as output for port 1 and 2 on the WAVESHARE RS485 HAT (SC16IS752)

# and then set the bit HIGH to enable the ports

GPIO.setup(TXDEN_1, GPIO.OUT)

GPIO.setup(TXDEN_2, GPIO.OUT)

GPIO.output(TXDEN_1, GPIO.HIGH)

GPIO.output(TXDEN_2, GPIO.HIGH)

# Now lets setup and inquiry packaet for the PR-3000-FS-N01, RS485 Anemometer

# Set the length of the transmit buffer

tx_buf = [0] * 8

tx_buf[0] = 1 # MODBUS ID

tx_buf[1] = 3 # MODBUS Function code (read holding register)

tx_buf[2] = 0 # Starting address of register - High byte

tx_buf[3] = 0 # Low byte

tx_buf[4] = 0 # How many registers to read - High byte

tx_buf[5] = 1 # Low byte

# Get the CRC of the packet

crc = _crc16(bytearray(tx_buf), 6)

# Add the crc bytes to the end of the transmit buffer

tx_buf[6] = (crc & 0x00ff)

tx_buf[7] = ((crc >> 8) & 0xff)

# pack the buffer

data = bytearray(tx_buf)

# Set board in transmit mode and write data

GPIO.output(TXDEN_1, GPIO.LOW)

ser.write(data)

# Waiting to finish sending

time.sleep(0.01)

# Set board to receive mode

GPIO.output(TXDEN_1, GPIO.HIGH)

# get six bytes plus crc = 8 bytes total

data_t = [0] * 8

for i in range(7):

data_t[i] = int.from_bytes(ser.read(1), 'little')

# Current wind speed example: 0056 H (hexadecimal) = 86 => Winds = 8.6m / s

# Add bytes 3 and 4 then divide by 10 to get meters per second

# Then divide by 1000 to get Kilometers per second

# now mutitply by 3600 to get kmh

ms = float(data_t[3] + data_t[4]) / 10.0

kmh = ms / 1000 * 3600

print('Kilometers per hour {0:>.1f}'.format(kmh))

# Typical response example

#b'\x01'

#b'\x03'

#b'\x02'

#b'\x00'

#b'\x56' Current wind speed: 0056 H (hexadecimal) = 86 => Winds = 8.6m / s

#b'\xb8'

#b'D'

This site is the personal blog and project repository of George Farris.

This site is the personal blog and project repository of George Farris.

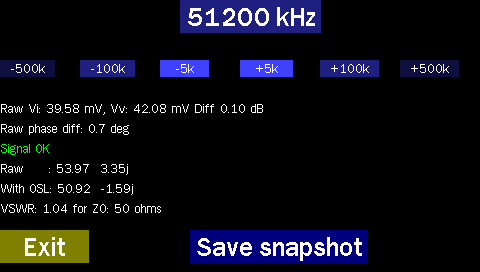

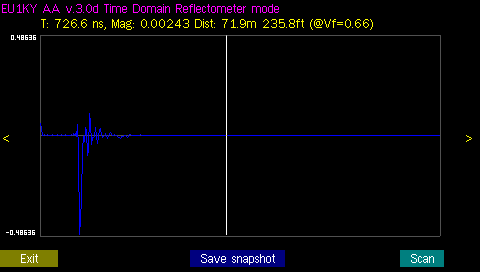

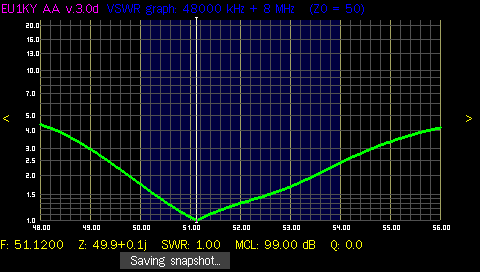

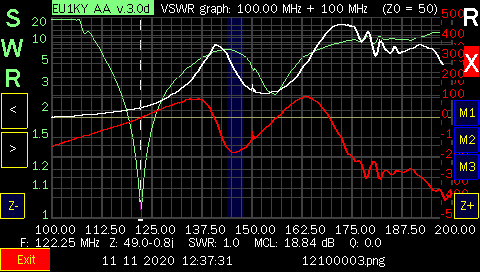

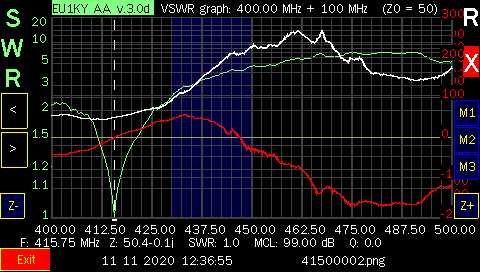

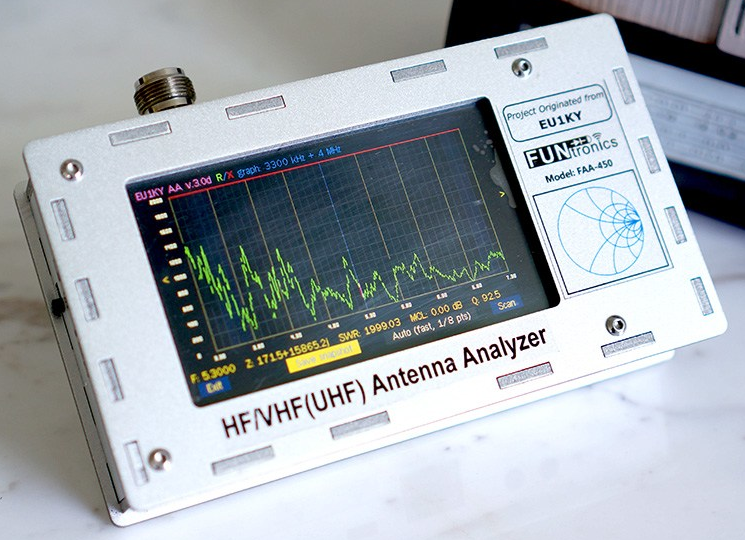

This page is a description of the modifications made to the EU1KY antenna analyzer project.

This page is a description of the modifications made to the EU1KY antenna analyzer project.